Driving automotive LED forward lighting systems

Discovering the driving forces behind the steadily increasing demand for LEDs in automotive front light systems: the quality of light and the European CO2 emission target for new passenger cars. By Luc Dang, Senior Technical Marketing Engineer, STMicroelectronics.

Design flexibility, reliability and high efficiency are commonly known advantages of LEDs over incandescent bulbs. Using LEDs for headlamps, however, means developers have to deal with multiple constraints; some are specific to the LEDs themselves, some to the automotive environment. Keeping in mind these challenges, STMicroelectronics has developed an innovative LED controller dedicated to automotive applications.

LEDs are undoubtedly a key light source for future automotive forward lighting systems. Although their implementation presents several technical challenges and more complex driving circuits, compared to conventional halogen bulbs, market reports predict a steady growth. Their benefits outweigh the challenges; long lifetime, robustness against vibrations, high efficiency and the design flexibility they offer means LEDs are predestined for automotive applications.

Using LEDs as a light source in vehicles is not a recent trend. They were introduced as low power signal lights for dashboard in the early 90s. They migrated to exterior lighting systems with centre high mounted stop lights and in the late 90s with rear exterior lights for tail lights, brake lights and blinkers. Today, more cars are equipped with LEDs for front blinkers, daytime running lights and even low and high beams, as the LED’s luminous flux and the efficacy are increasing.

In the past, the main objective of lighting systems was to fulfil regulation requirements, with minimal differentiation options and at minimum cost. Today the styling freedom offered by LEDs has turned these applications into a selling argument. They show the technological content of a vehicle and enable brand signatures, and the design possibilities it offers is now one of the main reasons for the adoption of LEDs in automotive.

Regulation

Regulations are also a driving force behind the increasing adoption of LEDs. In addition to the aforementioned drivers, the use of LEDs in front lighting is also driven by European regulations. For example, daytime running lights (DRL) have been mandatory since February 2011 for new passenger cars in the European Union. In parallel, targets for CO2 emissions have been defined. From 2012 on, substantial penalties have been applied if the carmaker’s fleet exceeds the limits: from 5 Euros to 95 Euros per gram of C02 per km in excess.

These already stringent targets (around 130g/km in 2012, depending on the car’s weight) will further decrease to 95g C02/km in 2019. At the same time, penalties will reach 95 Euros per gram C02 in excess per car. Therefore, each system in the car must bring its contribution to reach the target.

LEDs convert electrical energy into visible light with a much higher efficiency than incandescent bulbs. Qualified white LEDs have an efficiency exceeding 130 lm/W (at 25°C and 350mA), while laboratory performances demonstrated an efficiency as high as 254 lm/W.

In comparison, a H7 halogen headlamp has an efficiency of around 26 lm/W. Therefore, the substitution of bulbs for LEDs is an opportunity to reduce the power consumption and the C02 emissions.

In particular, a study shows that an exterior full LED lighting system in 2012 saves in average 2.4g C02/km compared to incandescent bulbs. Of all the exterior lighting functions, DRLs and low beams have the highest potential in terms of energy savings when LEDs replace incandescent bulbs. This is due to the high usage rate for DRLs on one side and the high power consumption of halogen lamps for low beams on the other side.

Another positive side effect of the usage of LEDs is the weight reduction of the cables. For a given function, the high efficacy of LEDs results in a reduction of the load current, and of the necessary current capability of the cables. Their cross section is therefore reduced, saving weight. This contributes in return to a further decrease of the C02 emission.

Quality of light

The luminous flux is the parameter normally used to characterise a light source, but it is not the only relevant parameter for low beam functions. The correlated colour temperature (CCT) also has an important influence on the human perception of white light sources.

Depending on the type of white LEDs, CCT range stretches from below 3000K (warm white) to 6500K (daylight corresponding to the midday sun, according to D65 standard) or more. Forward lighting systems uses cool white LEDs. For reference, halogen and HID lamps (D3S type) have a CCT of respectively 3200K and 4000K.

Experiments show that a white light source with a CCT of 4000K and with a reference intensity of 100% is perceived as being equivalent to a light source with a CCT of 6200K with a relative intensity of only 63%.

For the same perception of the light quality, low beams with cool white LEDs require less luminous flux and power than halogen or HID low beams. This consideration brings an additional potential for the reduction of C02 emissions.

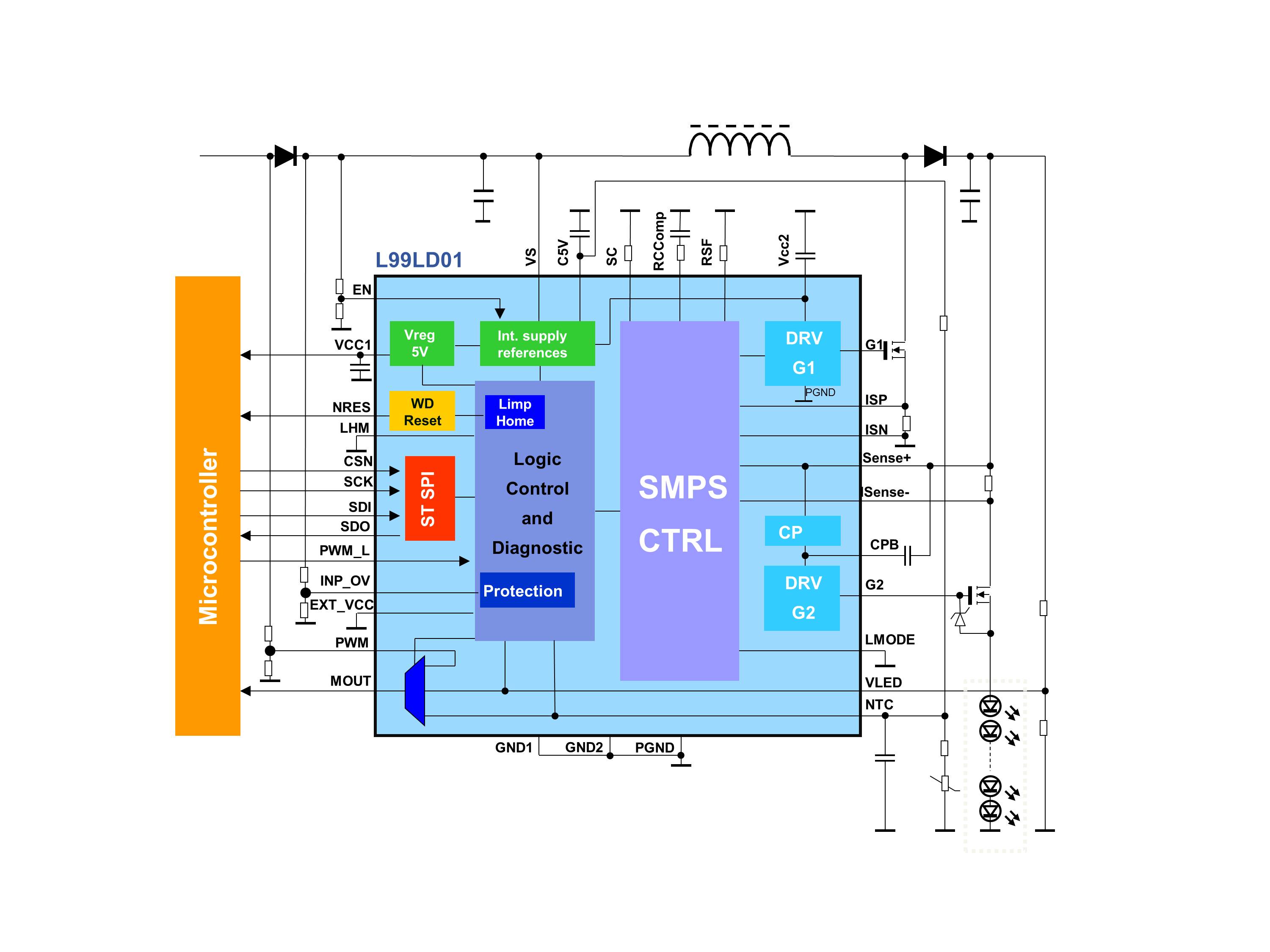

Figure 1: Block and typical application diagram of the L99LD01 in boost configuration

Electrical/Hybrid electrical vehicles (EV/HEV) is another driving force for all-LED lighting systems. One of the main challenges for EV/HEV is their range, which makes the energy efficiency a crucial parameter. Undoubtedly, LEDs will be widely used in such cars, as every Watt counts when it comes to range extension. Indeed, it is already possible to realise low beam and daytime running light functions with LED modules, whose input power is as low as 19W and per side 5W respectively. These functions require 65W and 25W per side respectively at a battery voltage of 13.2V, when using classical bulbs. Using LEDs saves 158W during night driving, if we assume an energy efficiency of 80% from the battery pack to the load.

Consider an electrical vehicle with an efficiency of 0.137 kW.h/km, 24kW battery pack and an average speed of 33.6km/h, according to New European Driving Cycle. The energy savings during night driving extends the vehicle’s range by 6km.

We have seen that the range extension of EV/HEV and the European regulations are driving factors for the penetration of LEDs in automotive front lighting applications. Moreover, high CCT white LEDs are quite close to daylight. This results in a better quality perception and an opportunity to reduce CO2 emissions of passenger cars.

Challenges

The LED’s forward current strongly affects its correlated colour temperature, therefore optimal control employs a constant current generator and PWM dimming capability in order to avoid colour shifts, while modulating the LEDs’ brightness.

Carmakers often use multi-platform LCUs, with the main motivational factors being the re-usability of the modules, the reduction of the development and manufacturing costs, the improvement of the quality and the simplification of logistic aspects. These control modules must not only cover several equipment levels for a given car model, but they also have to be compliant with the specific requirements of different regions.

LCUs have a long life cycle of about 15 years which must be compatible with the LEDs’ much shorter technology lifetime, due to their continuous performance improvements. Switching from a mature LED technology to the newest one results in cost reduction on one side and modification of the LED’s electrical parameters on the other side. LCUs must be flexible enough to drive different LED modules with a wide range of forward currents and voltages without any modification of the hardware.

There are also requirements inherent to automotive applications; the LCUs are located close to the headlights and are subjected to high ambient temperatures. Low beams and front blinkers are safety relevant functions which are often classified as ASIL B, according to the functional safety standard ISO 26262. Moreover, switched mode power supplies are by nature noisy systems due to their switching activity at high frequencies. The stringent EMI limits must be nevertheless met.

Keeping all these challenges and requirements in mind, STMicroelectronics has developed an SPI driven boost controller, which is dedicated for automotive environments.

Solutions

The L99LD01 integrates a DC/DC controller which operates as a constant current generator, and a gate driver for a dimming external MOSFET for optimal control of the LED string. The light output is controlled by varying the duty cycle in order to adjust the average current which flows through the LED string.

The device is compatible with a wide range of LED forward voltages and currents, without hardware changes. This allows multi-platform approaches..

The first point is achieved thanks to the various topologies the DC/DC controller supports; if the LED’s forward voltage can be either higher or lower than the operating battery voltage range a SEPIC, flyback or floating buck-boost (also known as boost to battery) should be used. If the LED string’s forward voltage is always higher than the maximum battery voltage, a boost topology should be used for a higher efficiency. The external switching MOSFET can be optimised to the LED strings’ power and length (breakdown voltage, Rdson and gate charge, for example).

The flexibility in terms of LED currents comes from the unique software configurability, which is provided through the SPI interface. The microcontroller can configure a wide range of LED current (analog dimming), with a granularity of 4.3%, without hardware modifications. Other parameters can be configured as well such as the threshold of overcurrent detection of the switching MOSFET, the watchdog period and so on.

Considering that the L99LD01 can control LED strings, which are assigned to blinker or low beam functions, the following features have been integrated in order to support high functional safety requirements. The timeout watchdog monitors the interface between the device itself and the microcontroller, as well as the microcontroller’s good operation. The L99LD01 reverts in a limp home mode if a watchdog failure is detected. In this mode, the converter operates as it has been configured in hardware, through a dedicated input pin. As any redundancy must be verifiable, some status registers provide information on the watchdog timer and the limp home input level. This concept allows a developer to build systems easily fulfilling ASILB functional safety requirements.

The L99LD01 provides full protection of the application, as it is often required in automotive environments: detection of input and output overvoltage conditions; monitoring of the LED temperature thanks to the NTC input; LED overcurrent protection, thanks to the high side current sensing, and; device overtemperature detection. The microcontroller can differentiate all these failures thanks to the detailed diagnostic, which is offered by the SPI interface.

The 5V regulator, which supplies up to 30mA, in combination with the reset control and the watchdog, forms a reliable power management for a small and cost effective 8-bit microcontroller.

Although the L99LD01 can supply, monitor, and communicate with the application’s microcontroller, the presence of the latter is not a prerequisite. The device is also able to operate in standalone configuration.

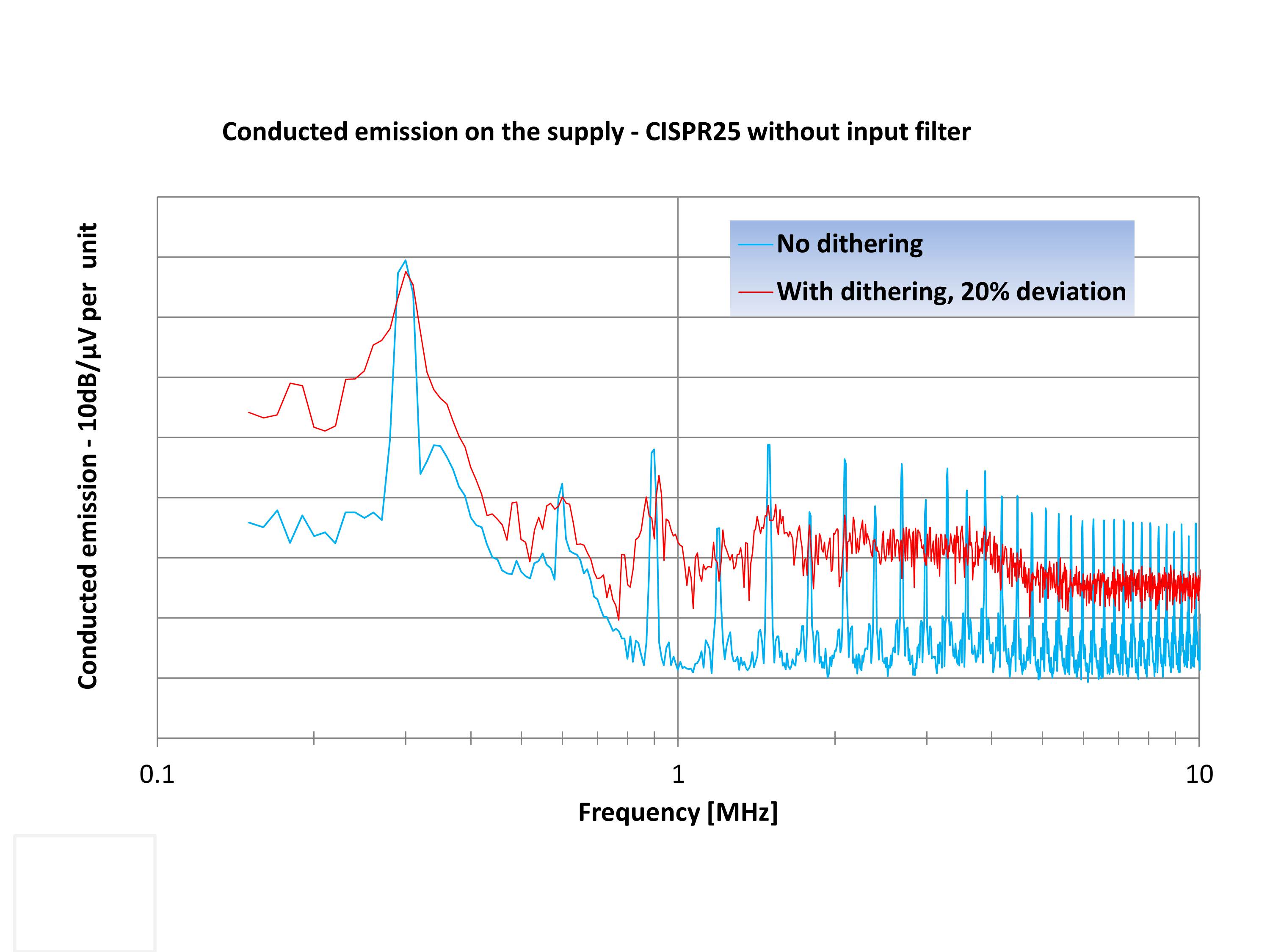

Figure 2: Measurement of the peak conducted emission on the supply, according to the CISPR25 method

As mentioned previously, switched mode power supplies are by essence noisy, and automotive applications must comply with strict emission limits so that it does not cause any disturbance to other electronic modules. To achieve this, the DC/DC controller implements a spread spectrum technique, also known as frequency dithering. The switching frequency is modulated, according to a pseudo-random pattern, in order to distribute the emissions over a wide frequency range, reducing the peaks’ amplitude. Figure 2 shows that this feature reduces the peak emission by up to 10dB/µV on certain frequency ranges (conducted emission on the supply line, peak measurement according to CISPR25, converter switching frequency: 300kHz, dithering deviation = 20%, no input filter at the input of the boost stage, output current: 1.0A, forward voltage of LED string ~ 20V, input voltage: 13.5V).

Using LEDs in automotive front light systems is an opportunity to reduce power consumption, as higher efficiency will become the norm. This helps to comply with the European Union CO2 emission limits for passenger cars, an aspect that will become even more important in the future, as the limits will be even more stringent and penalties will increase from 2019 on.

Powering these light sources requires a dedicated LED controller, which is tailored for this very specific environment. The L99LD01 makes the challenging specifications of LCUs easier to fulfil. Its SPI interface offers a detailed diagnostic and a high level of configurability, to support generic platform approaches while supporting high functional safety standards.